The Basics of Plastic

Let’s start from the beginning.

What is plastic? Where does it come from, how much do we use, and what is recycled? What different types of plastic exist, and how do you recognize them? Here we cover the basics of plastic to get you up to speed quickly with the material you’re going to be working with!

Pro-tip: look under your plastic product and see if you can recognize what type of plastic it is.

What is plastic?

Plastic is everywhere around us.

The word plastic is in our mouth day in and day out, but what does it really mean? The word itself is derived from the Greek plastikos meaning “capable of being shaped or moulded” and refers to their malleability during manufacture that allows plastic to be cast, pressed or extruded into a variety of shapes—like films, fibres, plates, tubes, bottles and much more.

Plastics are synthetic chemicals extracted mainly from petroleum and made of hydrocarbons (chains of hydrogen and carbon atoms). Most plastics are polymers, long molecules made up of many repetitions of a basic molecule called a monomer and this structure makes plastic particularly durable and long lasting. Due to their relatively low cost, ease of manufacture and versatility, plastics are used in an enormous and expanding range of products, from shampoo bottles to space rockets. The ubiquitousness and sheer volume of plastic production (it’s everywhere!) is causing serious environmental damage regarding its slow decomposition rate (recent studies say 500 years) due to its strong bonding molecules. Think of it this way, all plastics ever used from your parents and grandparents and great grandparents are still around today and will pollute the planet for another four centuries.

Most plastics contain other organic or inorganic compounds blended in called additives to improve performance or reduce production costs. The amount of additives ranges widely depending on the application and plastic type.

So, you can find it everywhere in the world, and it ends up in places we definitely don’t want it to be.

We produce 300 million metric tonnes of new plastic every year 🤯

Which is not very smart, especially when we have so much already existing material that we can use. Virgin plastic is made from oil, a valuable fossil fuel which we’re running out of, and it’s used to make cheap products which are meant to be discarded after a very short time of usage. This isn’t very smart. A huge design fallacy. And, as less than 10% of plastic is actually recycled, most of all this newly produced plastic ends up in landfills, the ocean, or is burnt. Huh?

So, how do we solve this? Well, it’s time to get recycling!

Pro-tip: alongside recycling you should try to minimize your use of new plastic.

Different plastic types

Firstly, there are two major categories of plastic: Thermoplastics and Thermoset.

Thermoset

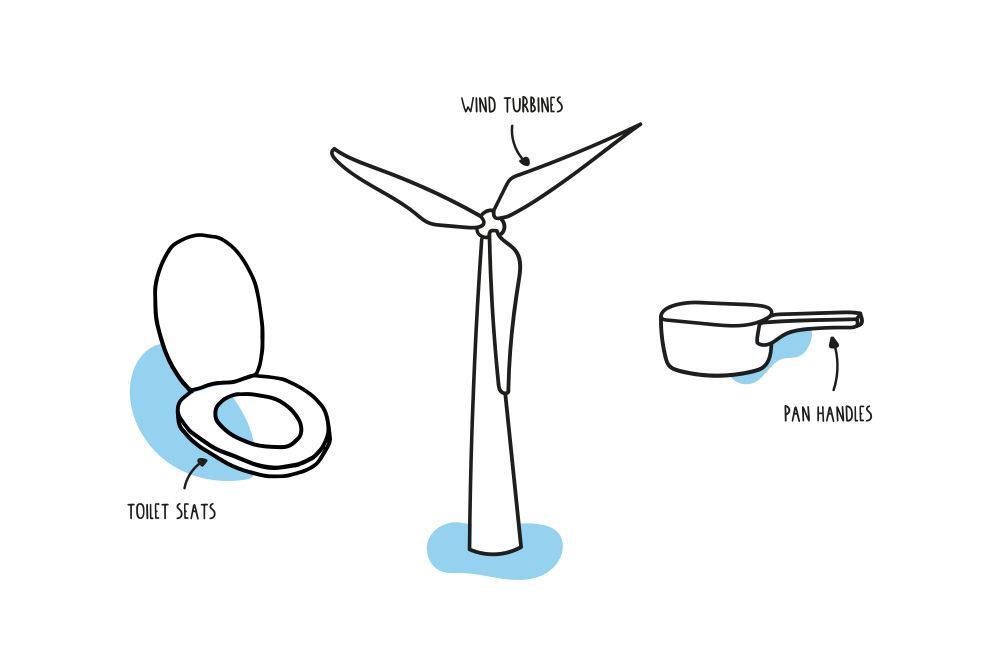

Thermoset plastics contain polymers that cross-link together and create an irreversible bond, meaning they can’t be remelted – once they take shape, they will be solidified forever. Think of Thermoset as bread: once bread is made, if you try to heat it, it just burns. None of these plastics can be recycled. Some examples of thermoset plastics are:

Thermoplastic

Thermoplastics is a plastic polymer which becomes soft when heated and hard when cooled. Thermoplastic materials can be cooled and heated several times: when they are heated, they melt to a liquid and when they cool they become hard. Think of Thermoplastics as butter: it can be heated and cooled many times, it just melts and sets again. Examples of thermoplastics:

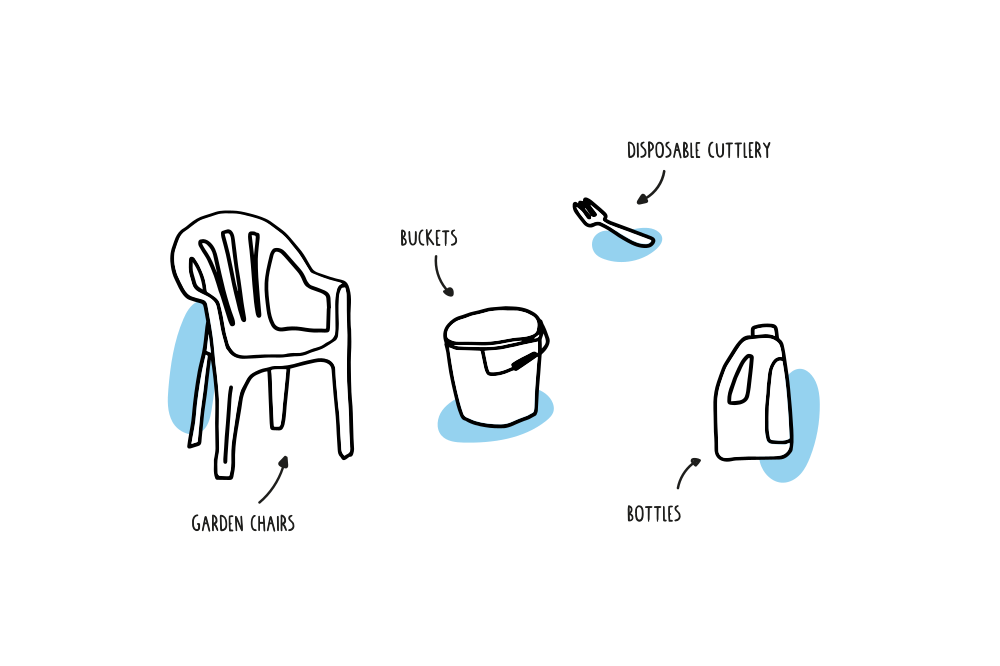

Thankfully, 80% of plastics in the world are thermoplastics (🎉) meaning they can be recycled and transformed. Thermoplastics (which we will just refer to as plastic) are divided into further subcategories depending on their structure and properties, and can be recognized by their name or number that should be usually printed or embossed somewhere on your products.

The most common ones are:

PET (1): Polyethylene terephthalate

PET is a very strong plastic that can be easily recognised for its transparent look – all water and soda bottles are made from PET as well as some jars, combs, bags, tote bags, carpets and ropes, and is recycled more commonly. Recently, PET has been recycled into yarns and made into clothes. This plastic is a bit more complex to work with, we advise to start with other plastics.

Properties: lightweight, impact resistant, rigid/semi-rigid

Pros: strong and stiff, water and oxide barrier, good electrical properties

Cons: high mold shrinkage, heat degradation, harmful fumes

Safety: Medium

Warning ⚠️ harmful fumes during processing, some research suggesting harmful materials seeping through long term use

Common uses: blow molded bottles (water bottles, soda/juice bottles), wrapping, film, electrical fittings

Best ways to use with PP machines: we’re working on that!

HDPE (2): High-density polyethylene

HDPE is often used for food and drink containers, as well as milk bottles, motor oil, shampoo bottles, soap bottles, detergents, bleaches, toys and bottle caps. Products of this plastic types are often easier to collect sorted and clean. HDPE works very well with Precious Plastic machines and is great to start with!

Properties: inert, thermally stable, tough and high tensile strength

Pros: cheap, high chemical resistance, electrical properties, waxy feel, good friction behaviour

Cons: less stiff than PP, easy to burn, poor UV resistance, high mold shrinkage

Safety: Good

Warning ⚠️ HDPE itself (when not burning) is not dangerous to use, however additives can be dangerous. It’s not possible to see what kind of additives are used in products.

Common uses: pipes, toys, bowls, crates, packing film

Best ways to use with PP machines: HDPE works very similar to PP, low melting temperature and easy to mould. Great material to use!

PVC (3): Polyvinyl chloride

PVC is toxic and we do not work with it. It is most commonly found in plumbing pipes and releases chloride when heated up – we do not recommend using with Precious Plastic machines!

Properties: insulating, chemically inert

Pros: cheap, acid and alkali resistance, flame retardant, stiff and strong

Cons: overheating causes degradation, brittle below 0°C, discolour in strong UV light, high density for thermoplastic, HCL and dioxins when burned

Safety: Not safe – do not use

Warning ⚠️ dangerous fillers and release of HCL and dioxins during degradation or burning.

Common uses: Flexible: fake leather, seals, cable covers, tape. Rigid: pipes, building products, bottes, film, soles, heat-shrinking tubes

Best ways to use with PP machines: don’t use it!

LDPE (4): Low-density polyethylene

LDPE is largely used for plastic wrap, sandwich bags, squeezable bottles, and plastic grocery bags. Usually LDPE is not commonly recycled, as it is often not labeled, it’s too light and tends to be more difficult to clean, but works rather well with Precious Plastic techniques. A popular recycling technique for plastic bags is ironing them into a more durable textile.

Properties: chemically inert, flexible, insulating

Pros: cheap, chemical and hydrolysis resistance, high impact strength (low temp), good processability

Cons: low tensile strength, low stiffness, low max temp, burns easily, poor UV resistance, high mold shrinkage

Safety: Good

Warning ⚠️ LDPE itself (when not burning) is not dangerous to use, however additives can be dangerous. It’s not possible to see what kind of additives are used in products.

Common uses: bowls, lids, toys, containers, fim, squeeze bottles, pipes, bags, sheets

Best ways to use with PP machines: LDPE is often a foil and not ideal to shred. But its good to fuse together with iron or used to create marble.

PP (5): Polypropylene

PP is one of the most commonly available plastics on the market, it is strong and can usually withstand higher temperatures. PP has a wide variety of uses but is consistently used for products that get in contact with food and drink – tupperware, yoghurt boxes, syrup bottles etc. PP works very well with Precious Plastic.

Properties: some properties here

Pros: like PE but stronger, stuffer and higher temp and lower density, mechanical, thermal and electrical performance result in a low cost engineering plastic

Cons: higher cost than PE, brittle below 0°C, high permeability to gases, poor resistance to fuels, poor UV resistance, keeps burning

Safety: Good

Warning ⚠️ PP itself (when not burning) is not dangerous to use, however additives can be dangerous. It’s not possible to see what kind of additives are used in products.

Common uses: structural parts, pipes, toys, chairs, kitchenware, DVD cases, packaging, films, textile, carpets, rope, netting

Best ways to use with PP machines: Works well with all machines! We love polypropylene!

PS (6): Polystyrene

PS is most commonly known as Styrofoam, but also appears in many more products. PS can be recycled, but not efficiently – recycling it takes a lot of energy which means that few places accept it. Disposable coffee cups, plastic food boxes, plastic cutlery and packing foam are made from PS – it works very well with Precious Plastic. It is one of the more toxic plastic types (so special attention please!), but at the same time offers great aesthetic and haptic properties as it is comparable with glass and can be polished. Properties: clear, glossy, hard, stiff

Properties: clear, glossy, hard, stiff

Pros: cheap, low mould shrinkage, good insulator, good on low temp

Cons: Brittle, poor wear resistance, poor chemical resistance

Safety: Medium

Warning ⚠️ While burning PS, styrene can be released (toxic)

Common uses: Toys, CD cases, light diffusers, electric housings, cutlery

Best ways to use with PP machines: extrusion, sheets, polishing (glasslike material)

MIX (7)

This code is used to identify other types of plastic that are not defined by the other six plastic types. Plastics such as. ABS, Acrylic or Polycarbonate are included in this category and can be difficult to recycle, however Precious Plastic can work with some of this.

Properties:As this includes a lot of different plastic types, the properties can vary a lot. So, it depends which type of plastic it is. If you can identify then you can reuse it but if it’s mixed, it’s chaos

Pros: There are some good plastics in here to work with. ABS, PLA, Nylon.

Cons: Hard to identify since they often don’t have their own label. So it gets mixed and is chaotic 🌪️

Safety: Hard to find the melting temperature, especially if it’s mixed. So you can easily end up burning it. So, not that safe.

Warning:Some of the plastic types included here (like PC) release very toxic fumes. Make sure to inform yourself about the plastic type you want to work with, and test its properties before processing it in masses.

Common uses:PC (CDs & DVDs…), PLA (bioplastics), ABS (3D-printing filament, toys, electronic products…), PMMA (acrylic glass)

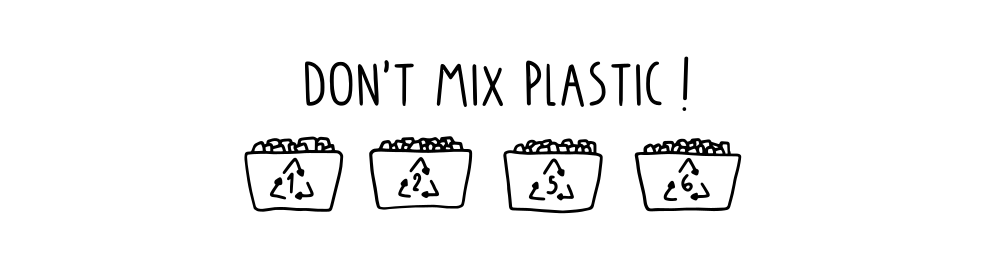

And always remember:

Different plastic types should never be mixed together as this will decrease their quality drastically and make it very difficult to recycle them. Moreover, when different types of plastics are melted together they tend to phase-separate, like oil and water, and set in layers resulting in structural weakness and lower quality products.

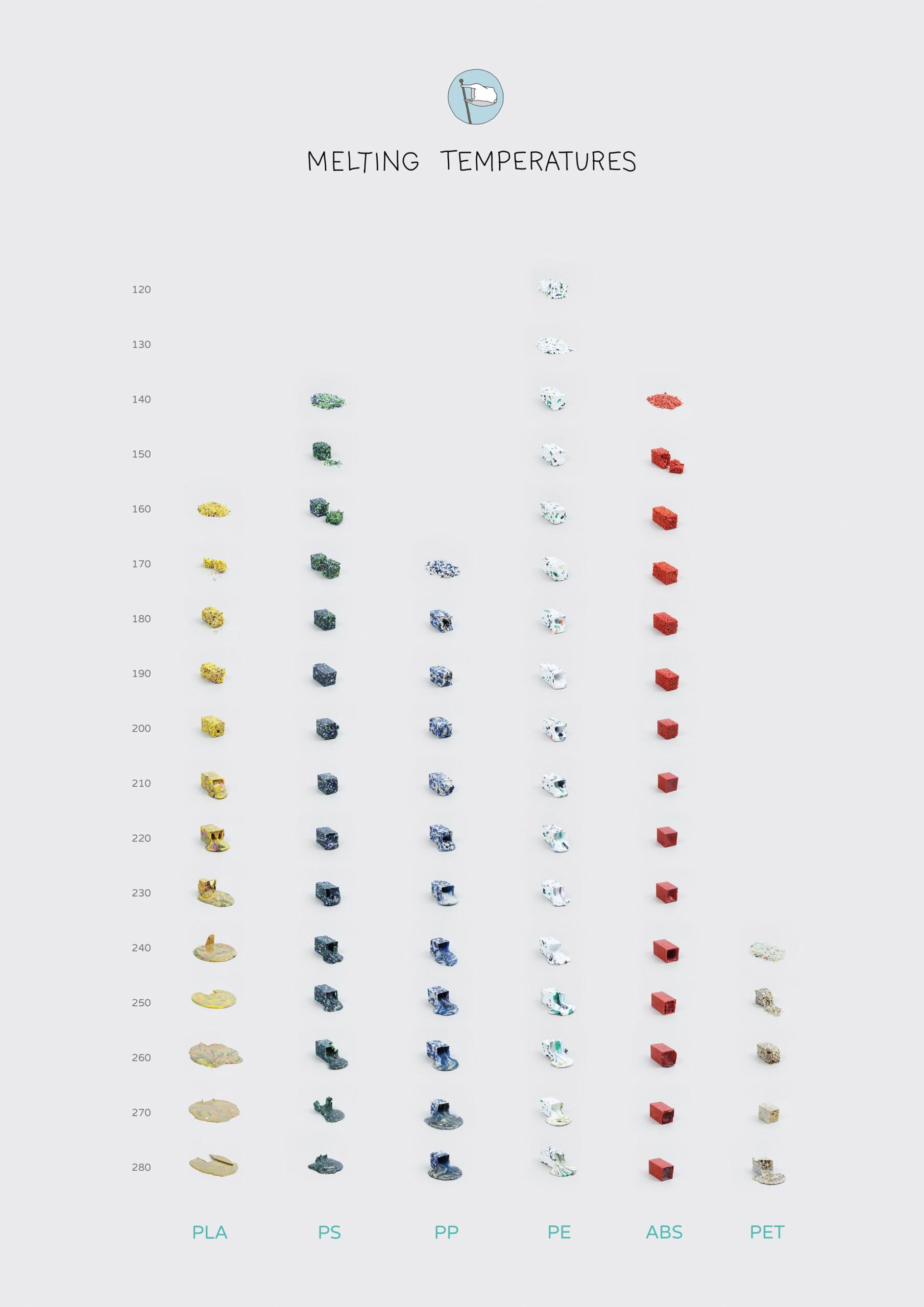

Melting temperatures

So, there are different types of plastic and one reason why it’s so important to separate them is because of their melting temperatures. They all reach a liquid state at a different heat, so in order to make new high quality items it’s important to know at what temperature each plastic melts, as well as at what temperatures different types can be moulded

Safety and Fumes

It’s important to take this seriously.

Safety is a huge topic when working with plastic, it’s extremely important to take the right precautions – then you are completely safe. We’ll walk through the dangers of fume exposure and which plastics are unsafe to work with, and we’ll go through how we set up our filtration systems at Precious Plastic.

Pro-tip: Try to melt your plastic at the lowest temperature possible and for the shortest amount of time.

Fume Dangers

The first rule is: don’t burn plastic. This one is very important. Why? It is extremely harmful to you, those around you and the environment. Very harmful toxins are released when burning plastic and can significantly increase the chances of cancer, respiratory illnesses and birth defects. It can also greatly damage internal organs and the hormonal system.

When burning PVC, dioxins are released which a highly toxic compound that has been shown to increase cancer, reproductive problems and immune system damage. At Precious Plastic, we don’t work with PVC.

If you do need to burn a small piece of plastic to identify its type, then do so taking the proper precautions: wearing a mask and beside a proper fume filtration system. The most important thing about working with plastic: You can melt it, you just can’t burn it. And that’s an important difference.

Volatile Organic Compounds (or VOC’s)

All plastics are made up of large molecules and when melted they make smaller molecule as fumes. These fumes are also called Volatile Organic Compounds and are very dangerous – immediate effects are severe irritation to the eyes, nose and lungs and prolonged exposure to fumes of any synthetic plastic with no safety precautions can lead to cancer, birth defects and illnesses..

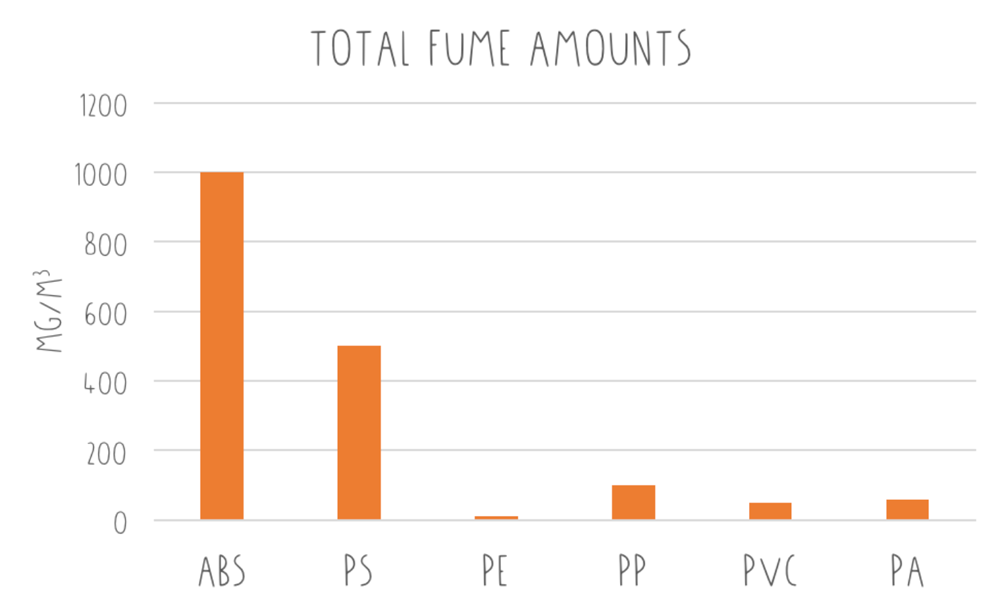

As seen in the graph below, fume contents of common plastics were studied by the Air and Waste Management Association, Chinese Academy of Sciences and The University of Tokyo. The studies concluded that ABS and PS created the most fumes: approximately 5 to 7 times more than the other plastics.

Fumes from ABS and PS contain styrene, benzene and ethylbenzene – these compounds are called cyclic compounds which create a lot of fumes and may cause cancer. Benzene is a human carcinogen, and styrene and ethyl benzene are probable carcinogens (probable carcinogen means that the compounds have not yet proven to cause cancer). Luckily, all of these cyclic compounds can be easily filtered with activated carbon, but more on that later!

The safest plastic to melt is PP and PE because they are low in cyclic compounds and they are essentially refined wax. PVC and PA are low in fumes but the contents are harmful to melt.

Fume Tests

For fume testing, we use a PID detector, which stands for photoionization – this detects the fume safety levels for VOC’s and can inform us where exactly the fumes are coming from. The advantage of using a PID sensor is that it’s very accurate and can be handheld, allowing us to design a flexible fume extraction system that we can move around.

When air enters the PID, a UV light interacts with the molecules in the air – organic compounds release positively charged ions when they pass through the light which are then captured by a negatively charged plate, producing measurable electrical current.

Our results:

In our workspace we detected fumes 2 cm from the source and it was approximately 14 times higher than the recommended maximum. PS created 5 times more fumes than HDPE and PP: this means that HDPE and PP are very low in cyclic compounds. We also detected where the fumes come from in each machine (more on that below).

We used a commonly used regulation: the maximum 3-hour concentration of hydrocarbon content is 0.24 ppm, not to be exceeded for more than a year [2]. In conclusion, our biggest threat is styrene vapor formed from PS melting.

Fume Sources from Precious Plastic machines

Ok, so where do fumes come out of Precious Plastic machines?

The Injection Machine

- Fumes come out from the nozzle when you take off the mold

- Fumes come out of the hopper when the injector handle is up

The Extrusion Machine

- Most fumes comes out from nozzle

- Some fumes from hopper when not blocked by pellets and from the mold openings

- For example, when making a beam, fumes come out at the end of beam mold

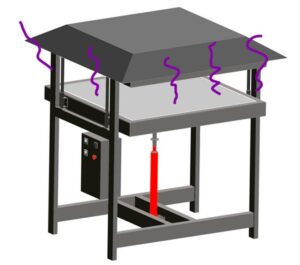

The Sheetpress

- Most fumes come out from all four sides

- If heating is uneven fumes come out from certain overheated areas

- Fumes were still coming out for 7 minutes at the cold press stage

Tips

- Wash plastic well before melting it. Residues from cleaning products can create harmful fumes.

- Never melt unseparated plastic, because different plastic types have different melting temperatures, meaning some plastic will burn before others are melted.

- When working with PS or ABS, make sure you don’t melt it for more than 8 hours per week, and always use a gas mask and ventilation.

- Don’t use a regular dust mask, that won’t work! Make sure you use an activated carbon filter gas mask. And make sure your gas mask is fitted properly!

- Try to melt plastic at the lowest possible temperature for the shortest amount of time

- If you ever feel dizzy, or it’s hard to breathe, move away from the fumes into fresh air.

- Keep away from the fume source – it’s 14 times higher than the recommended maximum exposure. If there’s no ventilation, you have to have a mask and stand about 2m away.

- Fume caddies with an adjustable arm is needed for extrusion and injection. For the sheet press, a fume extraction hood should be included in the machine design.

- Buy a low-cost VOC detector to check if the air in the workshop area is safe, and to check if the filter is working correctly.

Safety Gear

When working with plastic, you should have an activated carbon filter gas mask, and a stand-alone extraction filter, which also uses activated carbon. It’s an incredible material, and a lifesaver! We chose to use this because it filters cyclic compounds very well and is easily found everywhere around the world. We also can build LEV systems with activated carbon filters into machines or specific areas in the workspace.

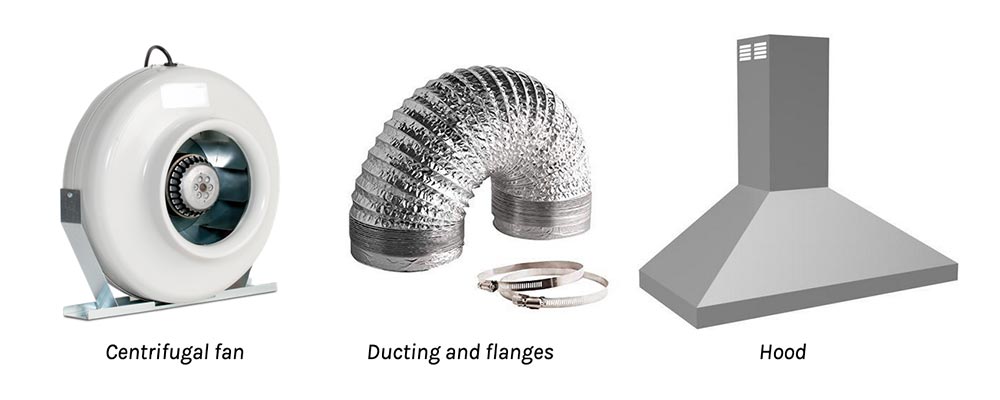

Ventilation (LEV)

LEV stands for Local Exhaust Ventilation, which is an industry standard to ventilate toxic air efficiently. This system is made of three parts: a hood for allowing contaminant clouds to enter the LEV, ducting which transfers air and the contaminant from the hood to the discharge point, and attached to a centrifugal fan with 780-1000 cubic meter (of what?) per hour.

Activated Carbon

Using an activated carbon filter (ACF) is the cleanest and easiest filtering method. It has a large surface area and is treated to have more pores than normal carbon – fumes stick very well to these pores making it a great material to filter out the nasty stuff. ACF will remove the following VOC’s very well: toluene, xylene, styrene, alcohol, benzene, decane, ethylbenzene, heptane and octane, and the following gases: pentane, acetone, hexane [3]. Porosity is the most determining feature of activated carbon. But they don’t last forever, you need to change the filter. While the compounds are invisible to us, they have a distinct smell that is normally filtered out. Once you can smell them, it’s time to change the filter.

Stand Alone Filters

A filter like this costs approximately 40-50 euros and has roughly 2-3 kg of granular activated carbon which needs to be changed each month(you can also get bigger filter which will last longer). These filters can be attached to centrifugal fans for the ventilation. Preferable conditions for using these filters humidity under 70% and ambient temperature lower than 80°C.

Buying carbon granules (for VOC removal)

When the filter needs to be changed, you do not have to buy a new filter. Instead, you can buy activated carbon granules to change the spent activated carbon – this spent carbon can be placed in a municipal landfill. It is best to buy activated carbon with Iodine number bigger than 1050mg/g – Iodine number is an indication of active surface area (the bigger the iodine number the better the filtration).

Gas Mask

A gas mask is also extremely important, as the filtration is not 100% so this acts as an extra barrier. Even in large industrial recycling and manufacturing they haven’t reached clean air, so gas masks are common practice. The most common masks are 3M masks and have four parts: the mouthpiece, the filter cartridge, a dust filter holder and a dust filter. They can be used for 50 hours before the cartridge and dust filters need to be replaced.

So, that’s it!

If you take the proper safety precautions of a proper gas mask and extraction filtration, you are safe. Don’t work with PVC or ABS, and the safest plastic to work with is PP, LDPE and HDPE. Remember though, you can only melt PS for up to 8 hours per week.